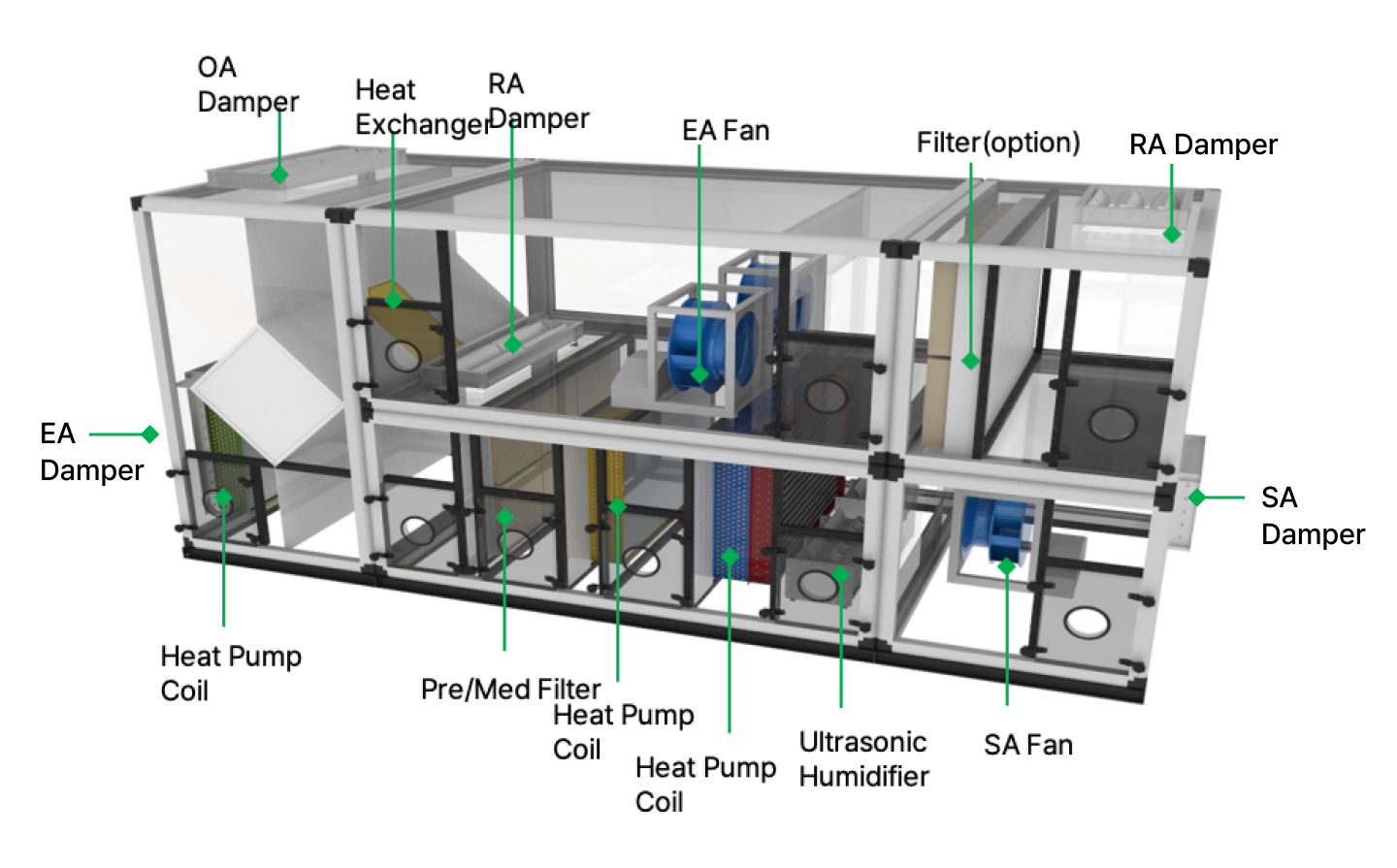

Equipment that recovers indoor waste heat while maximazing the efficacy of the heat pump cycle to minimize power consumption for cooling/heating sources and achieve optimal indoor ventilation. Combination of Heat Exchanger & Energy Saving Equipment Energy-saving air handling unit.

※ Optional: Exhaust line HEPA filter, chemical filter, UV lamp

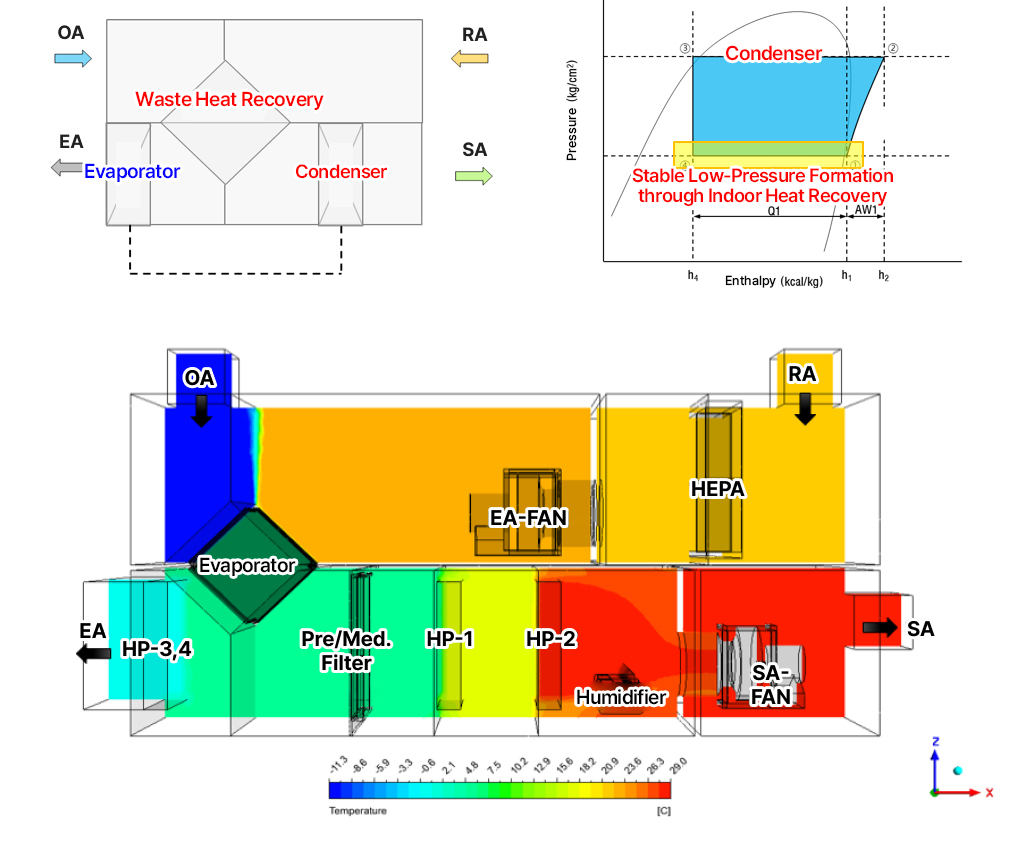

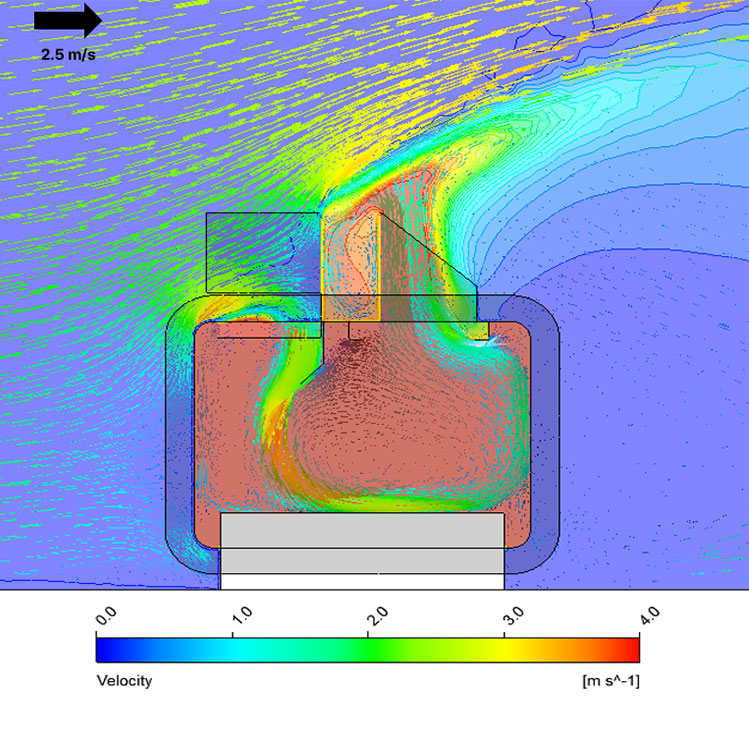

Overcomes the drop in cooling performance caused by fluctuating outdoor loads in

winter

→ Maximized heat pump performance by recovering indoor waste heat to

maintain a constant evaporator temperature

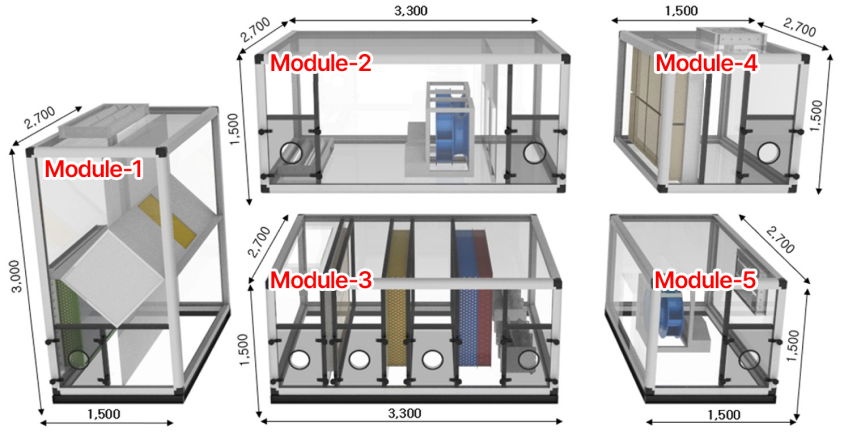

Sample) 20,000 CMH C.H.E.E.S.E energy-saving air handling unit module configuration

Modules manufacturing per unit airflow capacity:

2,000 CMH / 5,000 CMH / 10,000 CMH / 20,000 CMH

- Dimensions

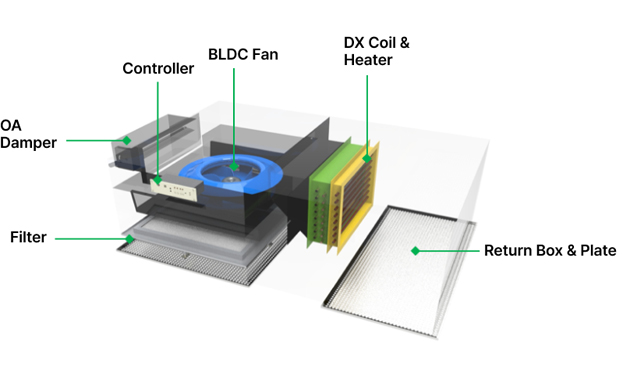

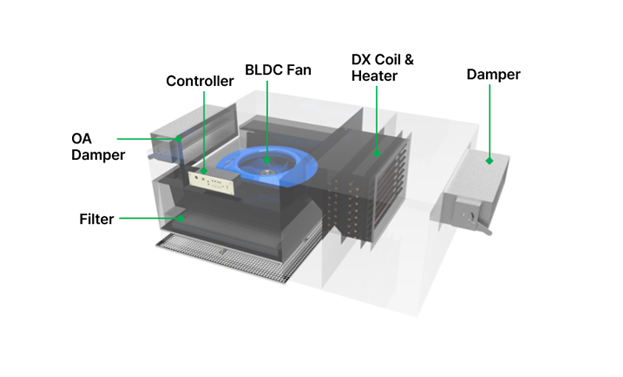

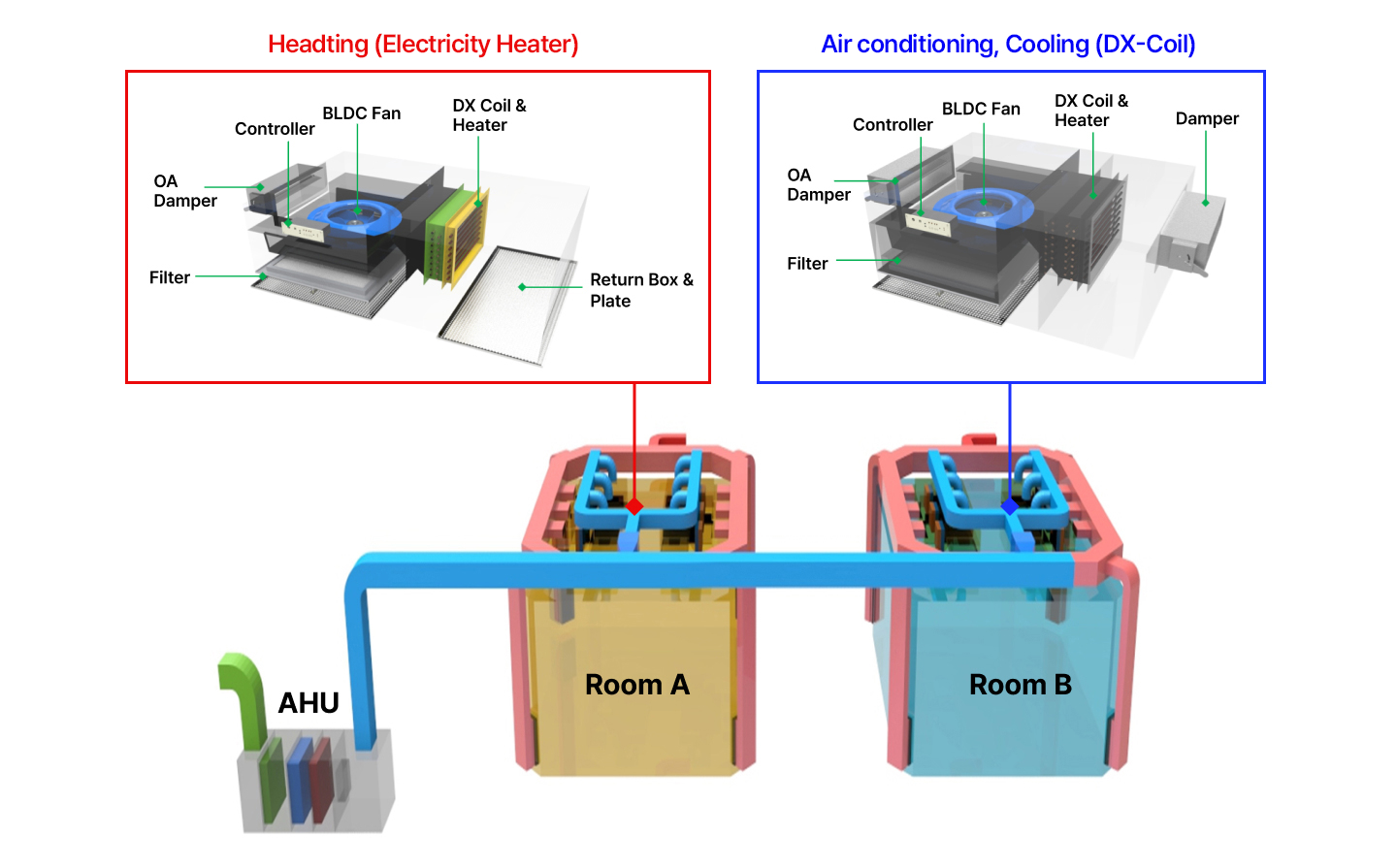

A device that enables individual heating/cooling control for each room within the same air-conditioning zoning, while supplying clean air through filteration.

Coil and Filter Equipment, Heating and Cooling Type Fan Filter Unit

General Type

Integrated Return Box

| Description | Model | ||

|---|---|---|---|

| General Type | Integrated Return Box | ||

| Dimension | W | 1,000 | 1,000 |

| L | 1,350 | 1,800 | |

| H | 580 | 580 | |

| Air Volume | Air Volume: RPM controllable up to max 30 CMM | ||

| External Static Pressure | 2.5 | ||

| HEPA Filter | 610 x 915 x 85(T) | ||

| Low-pressure loss type, ≥99.97% DOP efficiency | |||

| Cooling Coil | DX. 0.5 ~ 1 HP | ||

| PTC Heater | Electric, 1.5 kW | ||

Set Temperature: 22°C

| Room | Room Temp. | Remarks |

|---|---|---|

| A | 27℃ | Can operate up to + 5℃ |

| B | 17℃ | Can operate up to - 5℃ |

Flowone provides customized dry rooms optimized for processes requiring low-humidity environments, such as cesondary battery, food, medical, pharmaceutical, and research facilities.

Hybrid Desiccant Dehumidifier (DP -60℃)

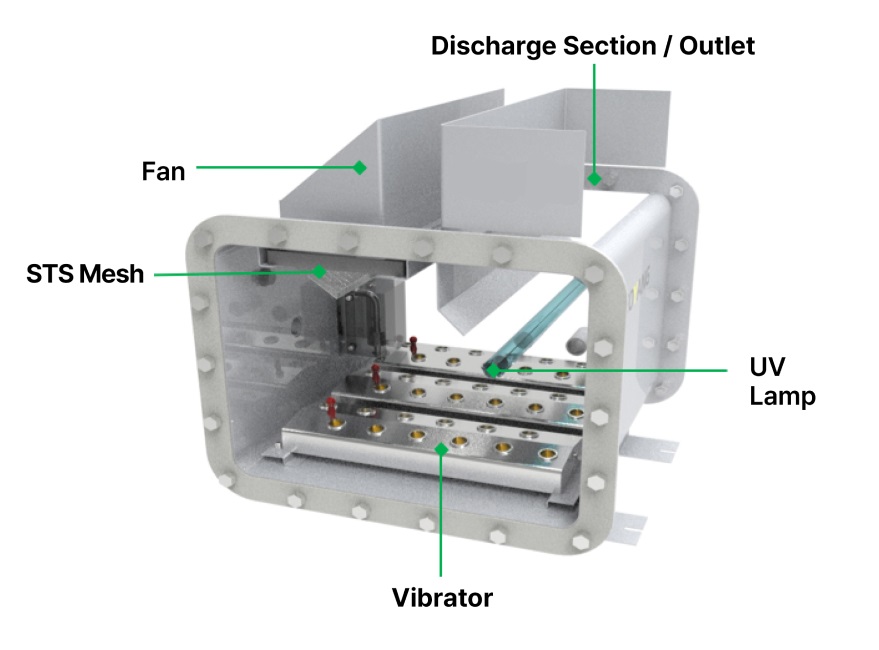

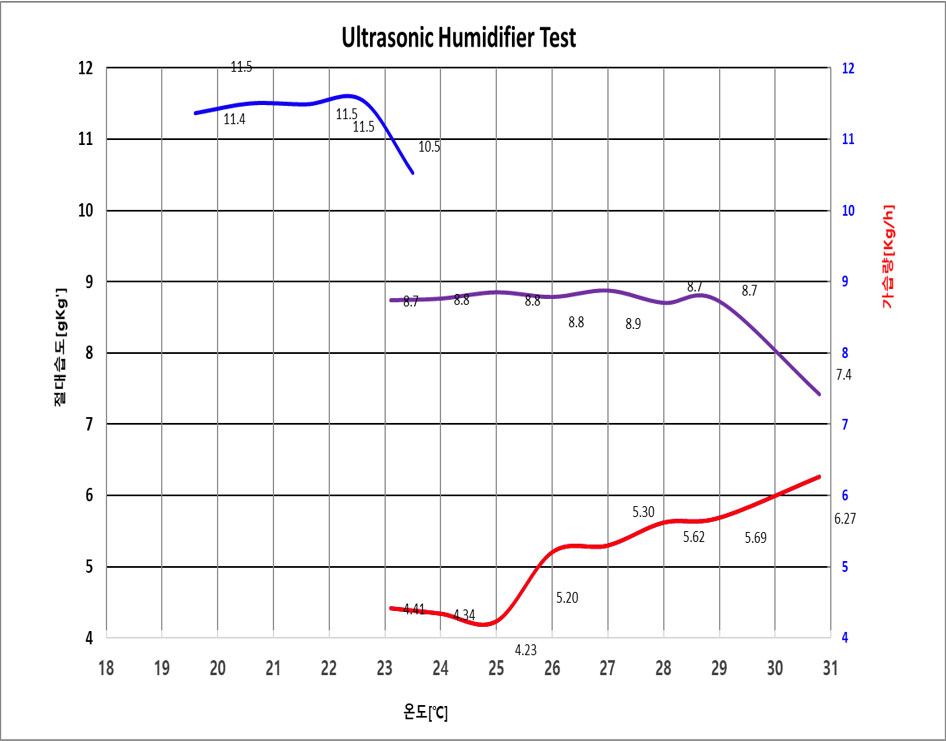

Sterilizing ultrasonic humidifier for air conditioning applications

Optional: Exhaust line HEPA filter, chemical filter, UV lamp

| Item | Description |

|---|---|

| Evaporation | 6-15kg/h, 16-45kg/h |

| Water Supply Pipe | 8A |

| Rated Current | 290-390W |

| Rated Power Supply | 220-380V |

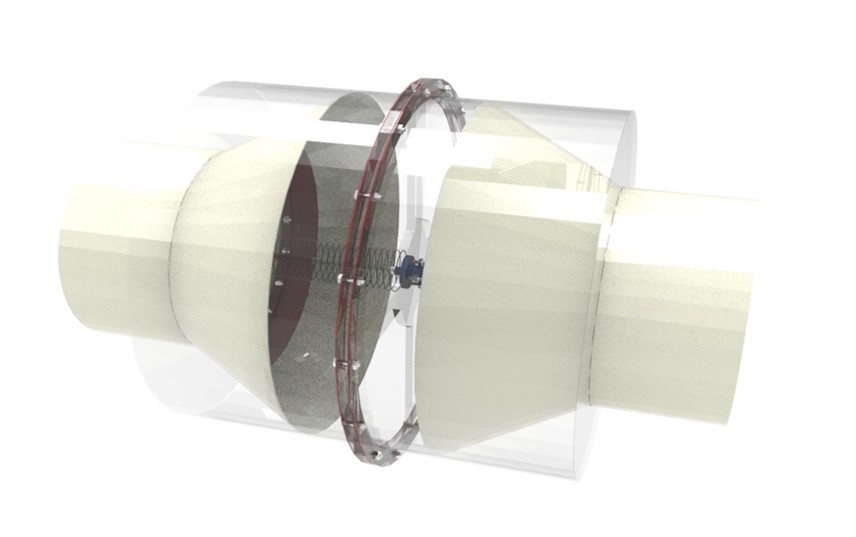

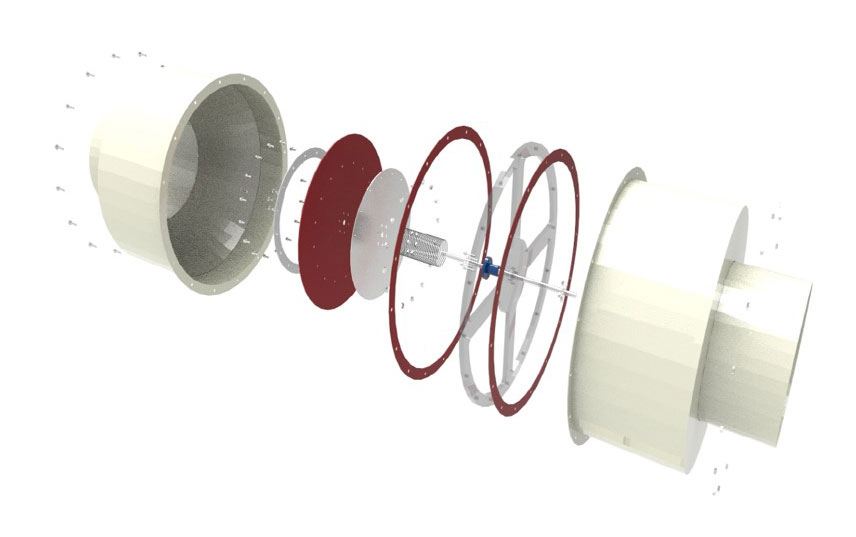

| Item | Description |

|---|---|

| Static Pressure Loss | 7 mmAq |

| Diameter | 250mm |

| Material | SCP or STS selectable |

| Remarks | Zero leakage at 40 mmAq static pressure test |